Technical Parameters:

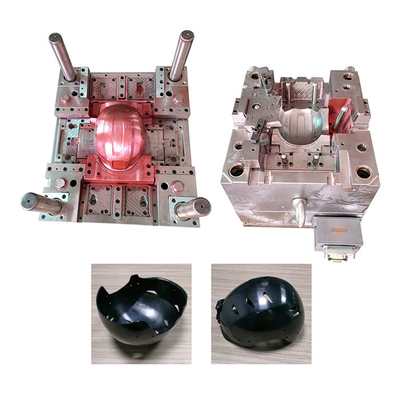

| Product Name | Plastic injection Mould |

| Core & Cavity Steel | S50C(45#),40Cr,P20H,718H,2738,5CrNiMo,38CrMoAC,H13,S136H |

| Steel hardness | HRC 28--50 |

| Molding Way | Compresion molding,Injection Molding |

| Mould Stardard | DME//LKM Standard Mould Base |

| Cavity Number | Single or Multi |

| Ejector Systerm | Ejector Pin,gas,Ejector Block |

| Lead Time | 35—50 days |

| Mold Life | >1,000,000 |

| Package | Wooden case |

| Size & Specification | According to customer's requirement |

| Quality Assurance | ISO9001:2000 Standard,Quality certificates |

| Material Supplier | ASSAB(Sweden), BOHLER,( ),SAARSTAHL(Germany),Daido(Japan),, Baogang(Shenzhen,China), LKM |

| Our advantage | 1. High Quality and Good after-sales service 2. Reasonable Price 3.Delivery On Time 4.Strict quality Control |

| Please feel free to contact us if you need more information about us. We will do our utmost to meet your requirments .Thank you ! | |

Custom Plastic Injection Molding Applications:

1. Plastic injection molding parts for architectural parts

2. Plastic injection molded auto components

3. Injection-molded household utility products

4. Plastic molded electronic enclosures

5. Plastic molds for medical & dental products

6. Injection molding parts for model shops, toys

7. Injection plastic parts for new product design & development

8. Custom plastic parts for construction

9. Injection plastic parts for others like cosmetic case

10. Plastic injection for Information Technology

11. Molded plastic parts for payment system

12. Precision plastic parts for Agricultural equipment

1. 3d Design/Samples for quotation

2. Start from part design analysis.

3. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

4. If product is complex, moldflow report will be present as well.

5. In house mold making shop ensure you mold quality under well control.

6. Normally it takes 20-40 days to make mold, precise time depends on part design.

industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, health care, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners.

1> Usually, your goods will be packaged in plastic bags, anti-shock foam, cartons, waterproof and environmental adhesive tape. For other individual demand in packaging, please specify in communication.

2> Unless specially asked for:

We choose DHL, Fedex for small package; ( 3-7 days )

UPS, TNT and Air Lift for big package. ( 7-11 days )

Personal offical express account and forwarder are all good.

For cheap shipping way and within 2kg, E-Post ( 7 days ) and China Post Air Mail ( 30 days) are available.

3> Usually non-custom process goods can be delivered in 3-5 days; custom process goods can be delivered in 7-30 days. Please consult for professional advise.

![]()

* Are you factory or trading company?

HOWE is a plastic mold factory in Dongguan, China, welcome to visit us.

* Is HOWE an ISO registered company?

Yes, GBM is an ISO 9001:2015 certified mold manufacturer, we take pride in our constantly improving process and always try to add

value for customers with the best efforts.

* What type of tooling services do you offer?

HOWE can help you manufacture, assemble and printing for your plastic parts. Besides normal molding process, HOWE has deep expertise of 2-shots molding, over-moulding and vertical insert molding.

* Do you have in-house mold design?

Yes, we have our own design team, our engineering manager has over 10 years' experience.

* How long it takes to design my mold?

The mold design timeline is dependent upon the complexity of the project. A simple construction mold can be designed in 1 or 2 days, while a complex mold can take several weeks. HOWE designers and project manager will work closely with you to design your mold in prefessional and efficient manner.